Commercial Bulkhead Stabilization in Georgia

Problem

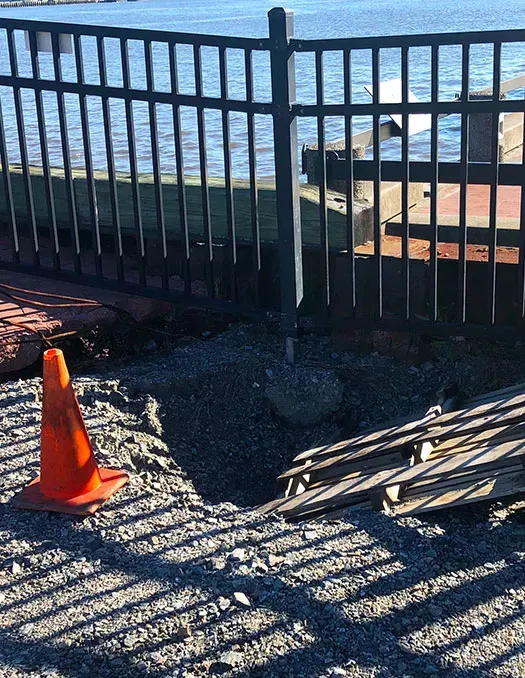

In Savannah, Georgia, a waterfront property on River Street serves as a loading / unloading terminal for popular river cruises that cater to the city’s important tourist trade. The property had an old steel sheet pile bulkhead that bounded it on the north and east sides. At some point in the past, the property had a newer bulkhead installed on the north side that turned the corner to the east but did not completely cover the older bulkhead on the east side. For over 10 years the property has been experiencing recurring sinkholes (or dropouts) behind the east side bulkhead. The property owner had the dropouts filled with sand, stone, rip-rap, and flowable fill over the years, but the sinkholes kept returning. With new sinkholes opening again, he decided to call URETEK.

Analysis

URETEK crews consulted with the owner and inspected the bulkhead along the north and east sides of the riverfront. The property owner was concerned about the regular sinkhole formation, but he was also concerned about interrupting cruise ship operations at the site. It became clear that the original bulkhead was the source of the problem. The original east-side bulkhead was constructed of sheet pile material, and over the years had likely experienced deterioration which allowed water to flow through. As water movement washed away fine soils, persistent dropouts kept forming behind the bulkhead at the surface. URETEK crews on site determined that URETEK Deep Injection® (UDI) would provide an ideal solution for the ongoing soil failure issues behind the riverside bulkhead, and that all work could be completed without interrupting the owner’s normal business.

Solution

Because the property is located within a historically significant part of Savannah, any solution would have to take into account significant tourist activity and an occupied hotel directly across the street from the project site. URETEK designed an injection grid that created two offset rows of injections to fill the voids, lock together the deeper soils, and seal the pathways where water was coming through the bulkhead. The injections were performed as deep as 32 feet below the surface grade to ensure that soil stabilization went well below the mud line. URETEK engaged a drilling subcontractor to help open holes for tube placement, due to the greater depth and the suspected presence of flowable fill.

Result

After just two days on site, URETEK grouted the soils behind the older sheet pile bulkhead along the east side of the property. The soils were stabilized to protect against future sinkhole formation, and all work was performed while the property was open for cruise ship boarding operations. The process that URETEK employed was the least disruptive solution available in terms of noise and time, and all work was completed without any disruption for tourists.

URETEK Deep Injection® (UDI)

Widely referenced throughout our industry, UDI involves the injection of structural polymer into base and subgrade soils to increase the load bearing capacity. This is achieved by injecting the polymer through small holes drilled directly through the pavement structure to depths determined by site-specific analysis. Our URETEK 486 Star® material flows easily into voids and weak zones within the soil mass below. Through a controlled chemical reaction, the expanding polymer compacts surrounding soils and applies a controlled pressure on targeted areas of the affected pavement above. If needed, a multi-injection design plan is utilized to gently return the pavement to its original grade. The composite material quickly cures into a strong, dimensionally stable, and water-resistant geo-material, providing years of reliable service.

URETEK 486 Star®

URETEK 486 Star® polymer is a two-component, high-density, expanding thermoset polyurethane system. It was developed to be the ideal solution for under-sealing, void filling, lifting of settled pavement, stabilization and stiffening of weak soils, and for encapsulating and sealing buried infrastructure. URETEK 486 Star® is environmentally inert, non-toxic, and resists underground water erosion or weakening due to its industry-leading hydrophobic properties.