Repairing Dale's Dips at Texas Motor Speedway

Problem

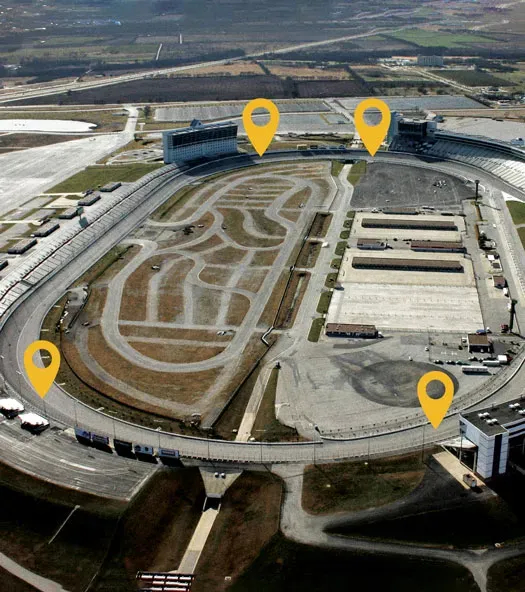

In the fall of 2006, Dale Earnhardt Jr. and other Nextel Cup drivers criticized Texas Motor Speedway for perceived “bumps” in the 1.5-mile track between turns one and two. The drivers said that these bumps prevented them from running “multiple grooves” on the track (the “side-by-side” racing that NASCAR fans crave) and made it difficult to control cars coming out of turn one. Texas Motor Speedway responded to this criticism immediately and hired surveyors to shoot elevations across the track to detect any track deficiencies. They determined that there were in fact areas of unlevel pavement, but these areas were settled “dips” instead of “bumps”. The degree of settlement was so slight that it would not have been detected on a city street, but given the aerodynamics of a race car, “Dale’s Dips” were an issue to some NASCAR drivers.

Analysis

Understanding the design of the Texas Motor Speedway track structure helps to understand the nature of the problem. The 60-foot wide banked turns sit at 23-degree angles and have large access tunnels underneath to provide infield access to racers and fans. In these turns, a four-inch layer of asphalt is laid over a one-foot layer of concrete which sits atop a nine-inch “drainage mat” of concrete. To support this heavy structure, it is imperative that the fill materials supporting the track are properly compacted. This became an issue around the access tunnels. The track settled slightly on both sides of the tunnels due to inadequate compaction of the fill materials.

Solution

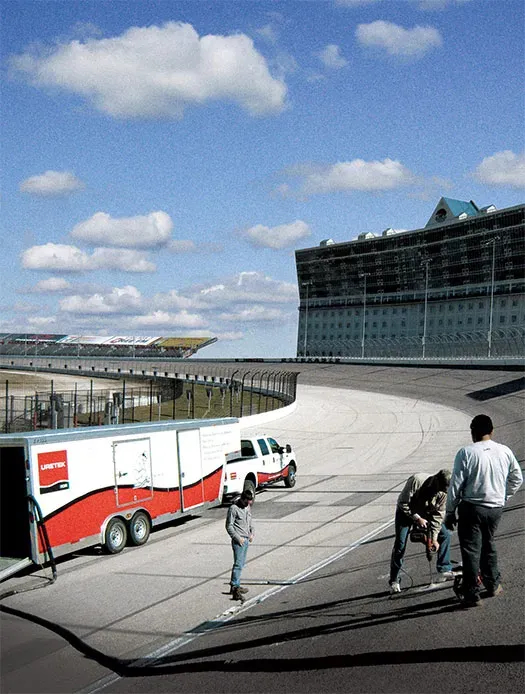

Texas Motor Speedway needed an accurate, long term, and timely solution. It was crucial to lift the track accurately because an “over lift” in any area would have severe, negative consequences for track officials. Further, the repair could not inadvertently compromise the racing surface which is meticulously maintained to optimize traction. The repair needed to be both permanent and timely because the facility hosts training and special racing events almost every week of the year. Any intervention, therefore, would need to stand up to rigorous use in both the short and long term. URETEK was selected to make the track repairs with their URETEK Deep Injection® (UDI) process. The URETEK crew drilled 5/8-inch holes into the track to precisely inject URETEK 486 Star® polymer at the proper depth. The rapid expansion of the material allows for incremental lifting; in this project, the URETEK team, working in conjunction with surveyors, constantly monitored the track levels to within hundredths of an inch.

Result

URETEK alleviated the troublesome dips from all four corners of the track. The entire lifting process was completed in three days and received high praise from Dale Earnhardt Jr. and other NASCAR drivers. There have been no additional reports of track settlement since the project’s completion. Thanks to URETEK, Texas Motor Speedway remains one of the best tracks in NASCAR.

URETEK Deep Injection® (UDI)

Widely referenced throughout our industry, UDI involves the injection of structural polymer into base and subgrade soils to increase the load bearing capacity. This is achieved by injecting the polymer through small holes drilled directly through the pavement structure to depths determined by site-specific analysis. Our URETEK 486 Star® material flows easily into voids and weak zones within the soil mass below. Through a controlled chemical reaction, the expanding polymer compacts surrounding soils and applies a controlled pressure on targeted areas of the affected pavement above. If needed, a multi-injection design plan is utilized to gently return the pavement to its original grade. The composite material quickly cures into a strong, dimensionally stable, and water-resistant geo-material, providing years of reliable service.

URETEK 486 Star®

URETEK 486 Star® polymer is a two-component, high-density, expanding thermoset polyurethane system. It was developed to be the ideal solution for under-sealing, void filling, lifting of settled pavement, stabilization and stiffening of weak soils, and for encapsulating and sealing buried infrastructure. URETEK 486 Star® is environmentally inert, non-toxic, and resists underground water erosion or weakening due to its industry-leading hydrophobic properties.