Bridge Stabilization Project in Schoharie County, New York

Problem

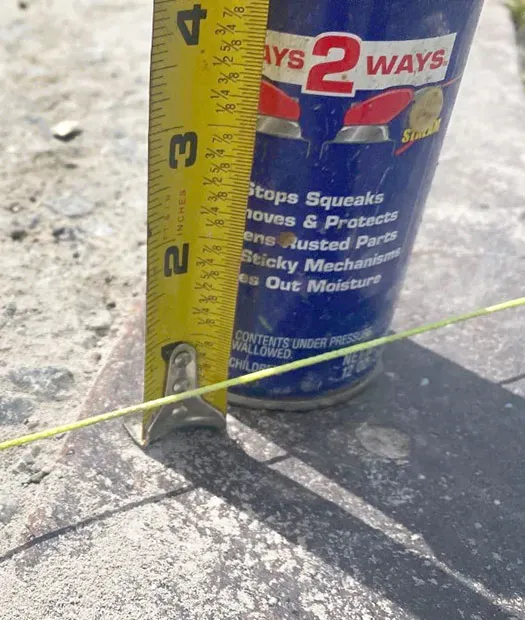

In Schoharie County, New York, a two-lane country road led to a single concrete bridge with an asphalt roadway abutting it. There was an approximate 1 ½”to 2″ settlement between the asphalt roadway and the concrete slab bridge approach that needed to be brought back to grade to prevent safety issues for low clearance vehicles like snowplows, which frequented the area.

Analysis

URETEK arrived at the location to determine a solution. Dynamic Cone Penetrometer (DCP) testing determined optimal injection depths for URETEK Deep Injection® (UDI) using a surface grid pattern of approximately 4’x 4′. This was to address the stability of the soils in each area that we would be injecting. Laser instruments monitored the surface to ensure sufficient soil stabilization.

Solution

For the bridge approach in Schoharie County, UDI was the perfect solution to fill the voids and stabilize the soils. URETEK drilled injection holes on 4′ centers and installed injection tubes in each location at various elevations as determined by the DCP. Crewmembers injected URETEK’s 486 Star® polymer through the tubes and into the soils beneath the base to fill the voids. Injections continued until 1mm of movement was detected at the roadway’s surface, confirming adequate soil stabilization. After the proper lift grade was met, URETEK performed a post-injection final profile in both lanes in areas they lifted off the roadway for warranty purposes.

Result

The project was deemed a success as the bridge approach/departure was lifted 1 7/8” back to grade. After a severe road maintenance hindrance in Schoharie County, NY, URETEK ensured quick, efficient, and long-term repair. To view a short before and after video of how the approach rides, please email regionally based Project Manager Mark Hurley at [email protected].

URETEK Deep Injection® (UDI)

Widely referenced throughout our industry, UDI involves the injection of structural polymer into base and subgrade soils to increase the load bearing capacity. This is achieved by injecting the polymer through small holes drilled directly through the pavement structure to depths determined by site-specific analysis. Our URETEK 486 Star® material flows easily into voids and weak zones within the soil mass below. Through a controlled chemical reaction, the expanding polymer compacts surrounding soils and applies a controlled pressure on targeted areas of the affected pavement above. If needed, a multi-injection design plan is utilized to gently return the pavement to its original grade. The composite material quickly cures into a strong, dimensionally stable, and water-resistant geo-material, providing years of reliable service.

URETEK 486 Star®

URETEK 486 Star® polymer is a two-component, high-density, expanding thermoset polyurethane system. It was developed to be the ideal solution for under-sealing, void filling, lifting of settled pavement, stabilization and stiffening of weak soils, and for encapsulating and sealing buried infrastructure. URETEK 486 Star® is environmentally inert, non-toxic, and resists underground water erosion or weakening due to its industry-leading hydrophobic properties.