According to the Federal Aviation Administration (FAA), our nations airports are busier than ever. With over 19,600 active public and private facilities servicing 2,790,000 passengers every day on over 44,000 individual flights, it makes sense that the FAA would have an opinion about runway maintenance.

In fact, the FAA does advocate for each public and private airport to create and stick to a Pavement Maintenance Program (PMP). According to the FAA, a PMP should include up-to-date records regarding pavement inventory and inspection, and should reference the FAA’s own guidelines and procedures for pavement system repair and maintenance.

Pavement Life Cycle

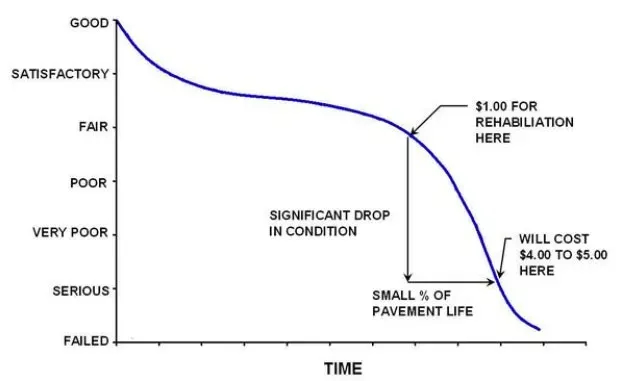

Pavement systems at our nation’s airports are all subject to what the FAA defines as the Pavement Life Cycle curve. This curve illustrates the useable life of a pavement system over time. The curve details how in the first several years of a pavement system’s life, deterioration in pavement condition is relatively low. However, the curve illustrates that as time moves on, pavement deterioration increases, resulting in an accelerated drop in pavement condition.

Delayed Maintenance is More Expensive

Importantly, the Pavement Life Cycle curve also points out the cost of delayed maintenance. As the curve makes clear, $1 spent for preventative maintenance early in the working life of a pavement system is equivalent to $4 to $5 spent later to address advanced pavement deterioration.

For airport administrators, the intent of a maintenance program is to keep the condition of the pavement as high as possible for the least amount of money. Because timely maintenance can renew the pavement condition, prolong the life of the pavement system, and exert clear economies on tight facility budgets, administrators across the country have come to rely on the speed, value, and long-term reliability of URETEK Deep Injection® (UDI). For the maintenance and repair of runways, taxiways, and associated pavement systems, there is no faster, less expensive, or more dependable solution.

Busy Airports Rely on UDI to Keep Air Traffic Moving

Beginning in 1989, with the introduction of URETEK Deep Injection® (UDI), this trusted pavement preservation method has been relied upon by administrators at our nation’s largest public airports, Air Force bases, and local general aviation facilities. Large or small, they all depend on UDI to stabilize soils, fill voids, and most importantly, maintain smooth and level runways, taxiways, and aprons.

UDI involves the injection of structural polymer into base and subgrade soils to increase their load-bearing capacity. This is achieved by injecting the polymer through small holes drilled directly through the pavement structure to depths determined by site-specific analysis. URETEK’s proprietary high-density polyurethane foam (HDPF) polymer material flows easily into voids and weak zones within the soil mass below. Then, through a controlled chemical reaction, the expanding polymer compacts surrounding soils, increasing their load-bearing capacity. The composite material quickly cures into a strong, dimensionally stable, environmentally inert, non-toxic, and water-resistant geo-material that provides years of reliable service.

Trusted Vendor for Airport Pavement Maintenance Programs

For over 30 years, URETEK has been a trusted, reliable partner for airport administrators intent on maintaining their critical pavement systems. With increasing air traffic loads across the country, the need for reliability and trust has never been more important than it is today. With its rapid response and crew scheduling that takes advantage of overnight and off-peak hours, URETEK is the vendor most prepared to complete pavement maintenance tasks without severely impacting flight schedules.

When we arrive, our crews get right to work on a site-specific repair or maintenance solution that quickly mitigates weak soil issues and extends the reliable working life of airport pavement systems. Best of all, our zero-excavation solutions mean the work is completed in days, not weeks or months. When the job involves stabilizing base and sub-base soils and restoring critical pavement systems to their optimal functional state, nobody does it better, or faster, than URETEK.

Contact URETEK today to learn more about our speedy pavement maintenance and repair solutions that keep budgets in line while assuring many more years of reliable service from runways, taxiways, and critical airport pavement systems.

Also, see our case studies to learn more about how our UDI application has successfully worked for airports across the country.